Customers often ask about our 3D capabilities for wire forming. This post describes how 3D CNC wire forming works.

Our three dimensional CNC wire bender can bend round and shaped wire into complex three dimensional wire forms. The CNC machine is programed via a touch screen panel. Our CNC machines have hi-speed servo motors and can cut high tensile material.

The machine starts with a wire coil payoff that feeds the wire from a coil and into the machine. Next comes wire straighteners and feeders that are used to straighten the wire. All wire comes with memory and the CNC machines first task is to erase that memory so that the wire comes out straight. The straightener comes with horizontal axis and vertical axis controls. This is an iterative process and requires a trained and experienced CNC operator so that wire forms come out straight and bends are made as designed.

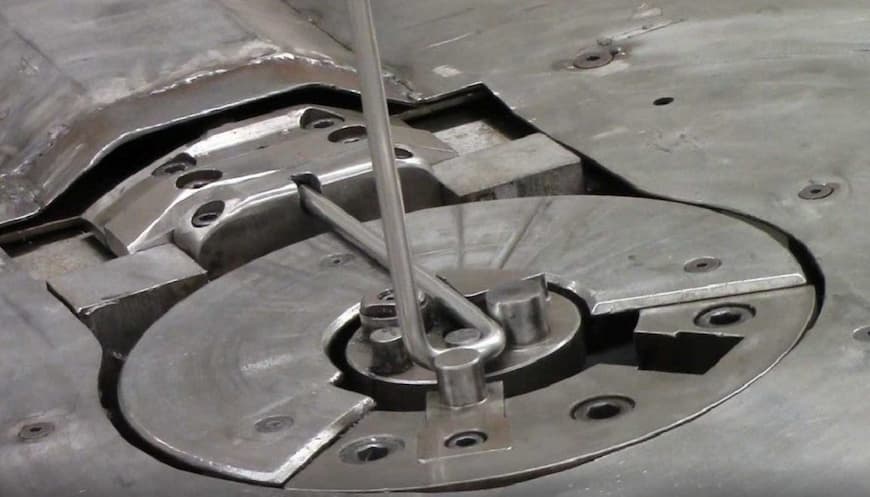

The next important aspect of the CNC wire former is the turret tool cluster that is used to make a series of wire bends using the pins on the tool cluster and the bending pins that are just outside of the tool cluster. The two bending pins can make a wide variety of bends and radii. The turret head contains a number of pins that allows for greater versatility, thus allowing for a greater variety of wire forms. Our tool clusters and bending pins are made for specific wire diameters. That helps to ensure that the wire being fed through the machine will stay true. The arm on the wire bender pivots around the wire so that three dimensional shapes can be formed. Finally, the horizontal cutter that sits on the arm cuts the wire.

All of our tooling is periodically inspected based on a maintenance schedule and sent to our tooling department to be re-calibrated. Our in-house tooling department allows us to maintain and modify our tooling so that we can make your wire products very efficiently.

Our CNC technicians and engineers go through in-house training programs that includes manual reviews, video instruction, theoretical tests, and practical tests. This ensures that they are adequately trained so that our 3D wire forms come out correctly and ultimately, so that your wire products are made efficiently.

Contact us now at [email protected] for more information on wire forming and wire products!