Pronto Products Co. is an ISO certified manufacturer of wire and metal products. Pronto was founded in 1959 in Los Angeles, CA. The company was approached by Glen Bell, the founder of Taco Bell, to create a metal basket to fry more than one taco at a time. We created the first taco shell fry basket for commercial use. Pronto continues to create custom wire and metal products for the largest foodservice companies in the world.

Over the years, the company evolved to manufacture custom wire and metal products for many industries, including the medical, aerospace, automotive, home appliance, sporting goods, and foodservice industries. We are pleased to see our wire and metal products in such a broad range of industries and to be the OEM wire and metal supplier of choice for many companies. Manufacturing custom metal forms and wire products is our passion!

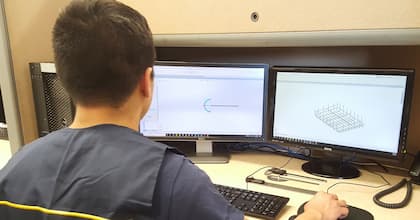

In 2013, the company commenced operations in Tijuana, Mexico. Our operations in Tijuana have continued to grow with our continued focus on manufacturing value added wire and metal products. We have a robust operation with engineers working in design, quality assurance, quality control, production, and automation. Our engineers work to deliver value every day for customers by optimizing our manufacturing process.

In 2020 we acquired Pacific Wire Products, Inc., a wire and metal fabricator based in Los Angeles, CA. Pacific Wire was founded in 1983 and had grown from a single person company to a 30,000 square foot plant, employing experienced and trained personnel, utilizing the most advanced metal fabrication equipment. Acquiring Pacific Wire provided Pronto with additional equipment, techniques, and capabilities.

We continue to focus obsessively on quality and efficiency. Our quality assurance program is built on three pillars – People Quality, Process Quality, and Product Quality. Training starts on day one and never stops. Our quality assurance engineers, quality control engineers, and quality control technicians are constantly looking at ways to improve our robust quality assurance program. A quality mindset permeates everything that we do.

Efficiency starts at the design stage of a product. It’s what we call “Design for Efficiency.” We invest in cutting edge wire and metal fabrication equipment and look for ways to manufacture in the most efficient manner. We optimize our supply chain so that we are able to purchase raw materials with the lowest delivered cost, without sacrificing quality. These savings are passed on to you.

Contact us today to see how our experienced engineers can help you now!